Press Molding Glass Forms

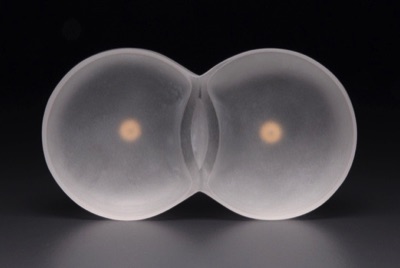

Two-part Translucence Series mold

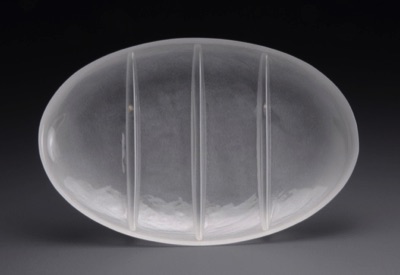

One-part Aqua Series mold

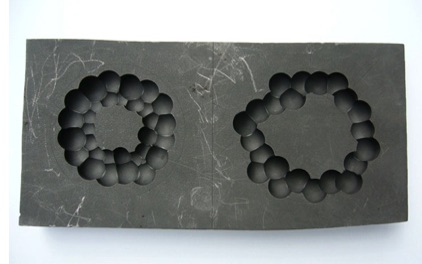

Two one-part Aqua Series Molds

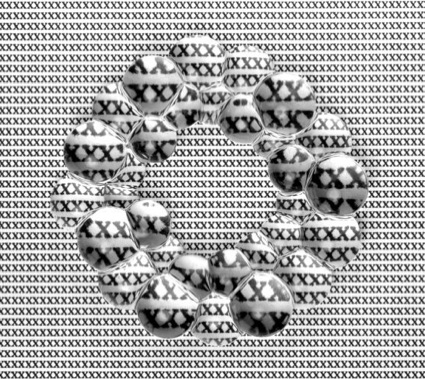

Two Magnification Series molds

Most of my Magnification Series and Aqua Series are made through a process called press molding into graphite molds. The molds are designed in computer aided design software (CAD) and then I use computer controlled machining (CNC) to carve the molds. In the press molding, 2000F glass is gathered directly from the furnace on a steel rod called a punty, and then dripped into the mold. Once the mold is full of glass, I press it down hard wiht a steel paddle.

After cooling in an annealer overnight, I cold work the glass extensively to refine the form. Below you can see both the molds and the glass that comes from them. Most of the time involved in this work is the cold working and the fabrication of the metal setting for the glass.

The video below is of a hot shop session of press molding at Studio Paran in Madison, WI, with Richard Jones as my gaffer. We are using an Aqua Series graphite mold that was carved using CNC and the mold is shown below the video along with a brooch that came from it.

Two one-part Aqua Series Molds that are in the video

Two-part Translucence Series mold

Two one-part Aqua Series Molds